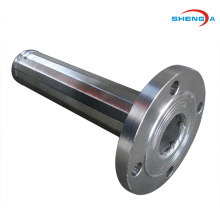

Basic Info

Model No.: RDZL-150

Click on the follow link to find out more information: https://www.rddryer.com/other-engineering-industry/

Company Info

- Company Name: Changzhou Ruide Drying Engineering Technology Co., Ltd

- Representative: Zhongxing Liu

- Product/Service: Melt granulator , Steel strip bonding machine , Drying Equipment , Sieving Equipment , Mixing Equipment , Granulating Equipment

- Capital (Million US $): 10,000,000RMB

- Year Established: 2015

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 3

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: Fewer than 5 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Jiaoxi Town, Wujin District, Changzhou City, Jiangsu Province

- Contact Person: Ms. Angel

- Tel: 86-519-68231907

Premium Related Products

Other Products

Hot Products

Hot Melt Adhesive for WoodworkingChina Supplier Melamine Magic Sponge Foam FactoryNatural Bamboo Fabric Anti Grease Dishcloths Cleaning Kitchen Products FactoryC9 Hydrogenated Resin / Hydrogenated C5 Petroleum Resin for Adhesive Qm120-BC5 Hydrogenated Petroleum Resin (DCPD hydrogenated petroelum resin)Low Odor C9 Petroleum Resin (cold poly) for Adhesives HS130-5C9 Hydrocarbon Resin Petroleum Resin Used for PaintHydrogenated C9 Hydrocarbon Resin for Psa Medicine Grade ResinIndustrial C5/C9 Hydrocarbon Resin Pressure Sensitive Adhesives Hg100-5Strong Base Anion Exchange Resin (201X7 CL)Water Treatment Strong Acid Cation Exchange Resin (001X8 NA)Hot Melt C5 Hydrocarbon Resin Light Color Low OdorEnvironmental C5 Hydrogenated Hydrocarbon Resin Used for Hot Melt AdhesiveC5/C9 Hydrocarbon Resin Used in AdhesiveC9 Hydrocarbon Resin Used in Rubber China FactoryChina Resin C5 Hydrocarbon Resin for Road Marking Paint Factory (001)