PCB PCBA for Industrial Machine Communication Connection

Basic Info

Model No.: 6layer pcb copper pour

Product Description

Is a 6 layer PCB good?

Over the years, high-density multi-layer has gained great popularity in various industries. Nowadays, it is easy to find several types of multilayer PCB, including 4-layer PCB, 6-layer PCB and so on. The 6-layer PCB has become an integral part of compact wearable devices and other mission-critical communication devices. What makes them popular? How are they different from other types of multilayer PCBs?

Introduction to 6-layer PCB

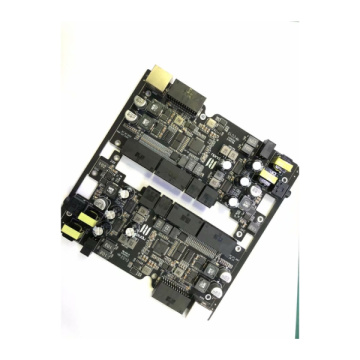

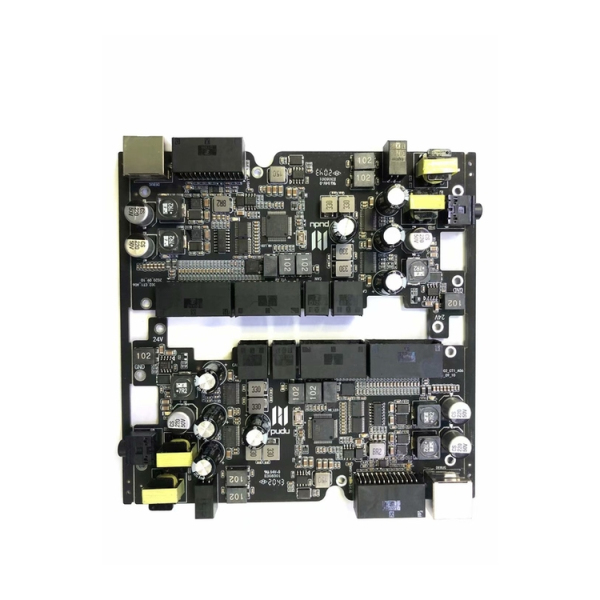

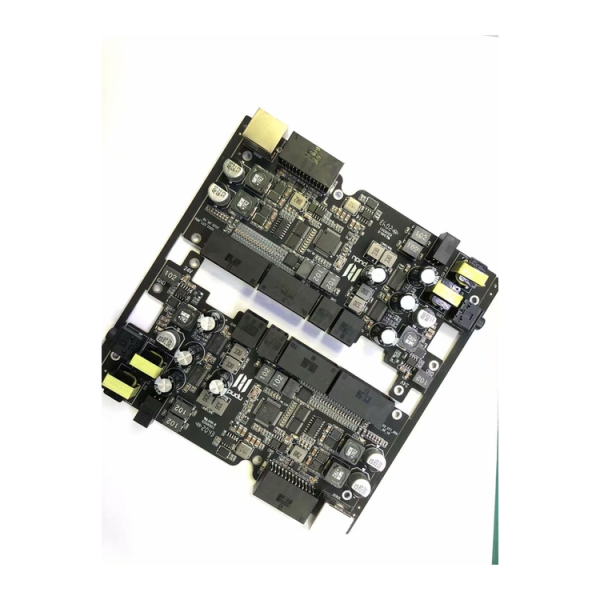

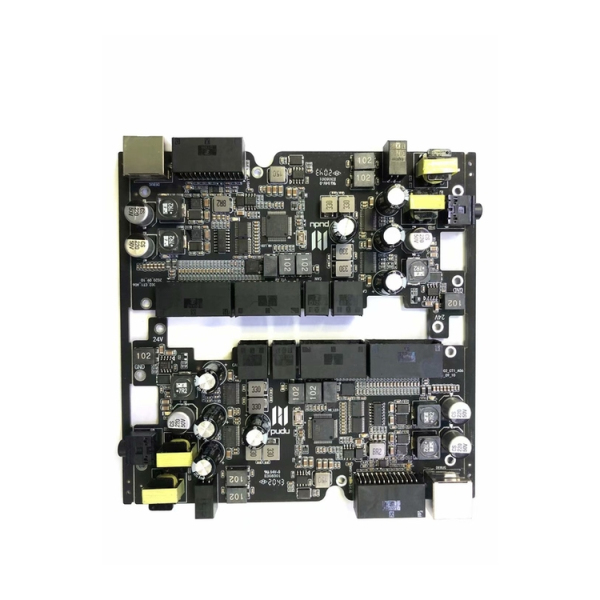

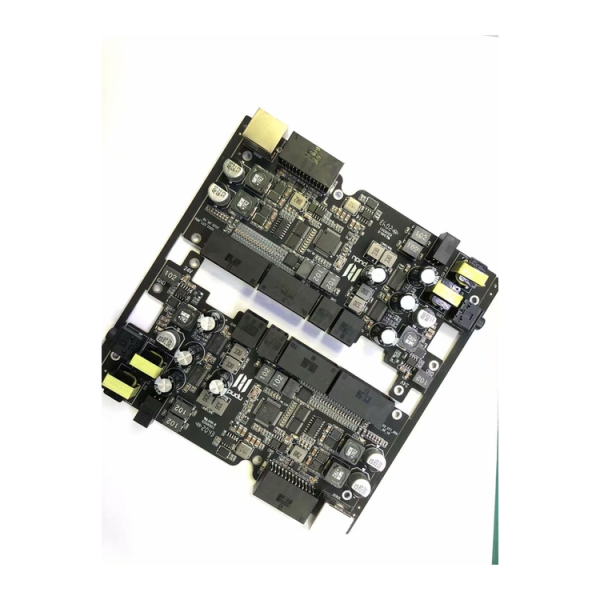

As the name implies, a six-layer PCB includes six layers of conductive materials. It is basically a 4-layer PCB with two additional signal layers placed between two planes. A typical Microwave radio frequency board 6-layer PCB stack has the following six layers: two inner layers, two outer layers and two inner planes-one for power and the other for ground. This design improves EMI and provides better routing for low-speed and high-speed signals. Two surface layers help route low-speed signals, while two internal buried layers help route high-speed signals.

The figure above shows a typical design of Microwave radio frequency board 6-layer PCB; however, it may not be suitable for all applications. The next section will focus on some possible configurations of a 6-layer PCB.

The figure above shows a typical design of Microwave radio frequency board 6-layer PCB; however, it may not be suitable for all applications. The next section will focus on some possible configurations of a 6-layer PCB.

Key factors to consider when designing 6-layer PCB stackups for different applications

The correct stacking of 6-layer PCB manufacturers can help you achieve better performance because it will help suppress EMI, use various types of RF equipment and include several fine-pitch components. Any errors in the stack-up design will seriously affect the PCB performance. Where to start? This is how you correctly choose the stacking method.

1. As the first step of stacking design, it is important to analyze and solve the number of grounding, power and signal planes that the PCB may need.

2. Ground planes are an important part of any stackup because they provide better shielding for your PCB. Moreover, they minimize the need for external shielding tanks.

Here are some proven 6-layer PCB stackup designs for various applications:

1. For dense boards that occupies a small area. Such as HDI PCB: If you plan to route a dense board with a small footprint, you can install four signal planes, a ground plane and a power plane.

2. For denser circuit boards that will use a mixture of wireless/analog signals: On this type of circuit board, you can choose a stack that looks like this: signal layer/ground/power layer/ground/signal layer/ Ground plane. In this type of stacking, the inner and outer signal layers are separated by two package ground layers. This laminated design helps to suppress EMI from mixing with the internal signal layer. The stack design is also ideal for RF equipment because the AC power supply and ground plane provide excellent decoupling.

3. For printed circuit boards with sensitive traces: If you want to build a printed circuit board with many sensitive traces, it is best to choose a stack that looks like this: signal layer/power layer/2 signal layer/ground /Signal layer. This stack will provide excellent protection for sensitive traces. This stack is suitable for High frequency boards that use high-frequency analog signals or high-speed digital signals. These signals will be isolated from the low-speed signals on the outer layer. This shielding is done by the inner layer, which also allows the routing of signals with different frequencies or different switching speeds.

4. For boards that will be deployed near strong radiation sources: For this type of board, the stack of ground/signal layer/power/ground/signal layer/ground will be perfect. This high frequency mixing pressure plate stack can effectively suppress EMI. This stack is also suitable for circuit boards used in noisy environments.

Benefits of using 6-layer PCB:

Because of the six-layer PCB design, they have become a regular function in several advanced electronic circuits. The following advantages provided by these circuit boards make them very popular among electronics manufacturers.

1. Small footprint: Due to their multi-layer design, these printed circuit boards are smaller than other circuit boards. This is particularly beneficial for micro devices.

2. Quality-driven design: As mentioned earlier, 6-layer PCB stack-up design requires a lot of planning. This helps to reduce errors in details, thereby ensuring high-quality construction. In addition, nowadays, all major PCB manufacturers are adopting various testing and inspection techniques to ensure the suitability of these circuit boards.

3. Lightweight structure: A compact PCB is realized by using lightweight components, which helps reduce the overall weight of the PCB. Unlike single-layer or double-layer PCBs, six-layer circuit boards do not require multiple Cable Connectors I/O Connectors to interconnect components.

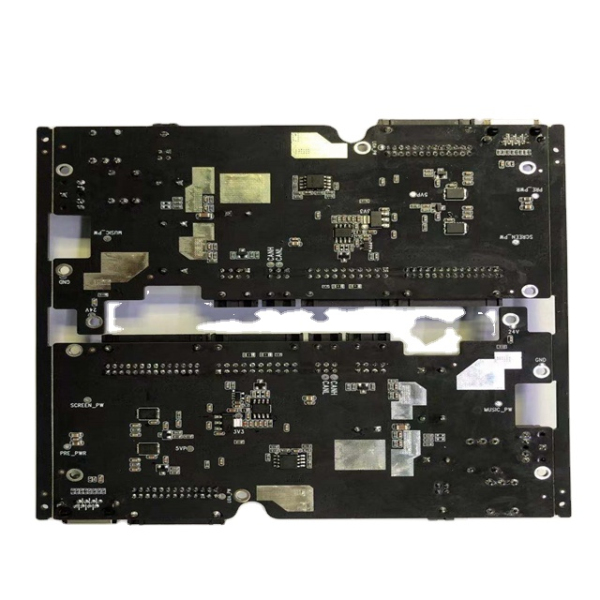

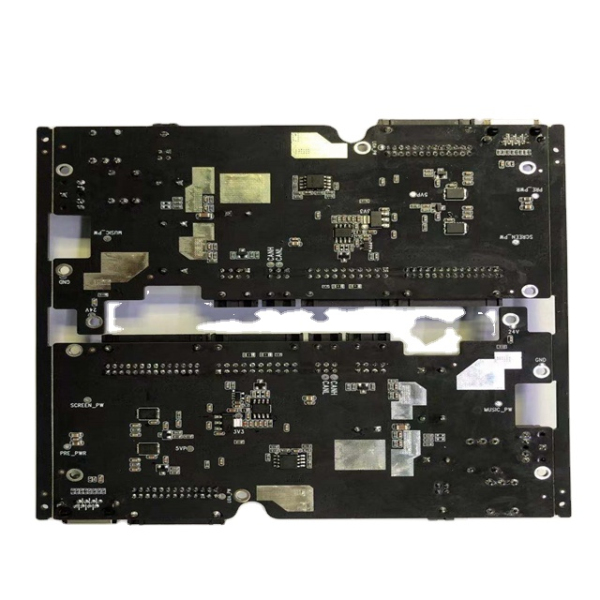

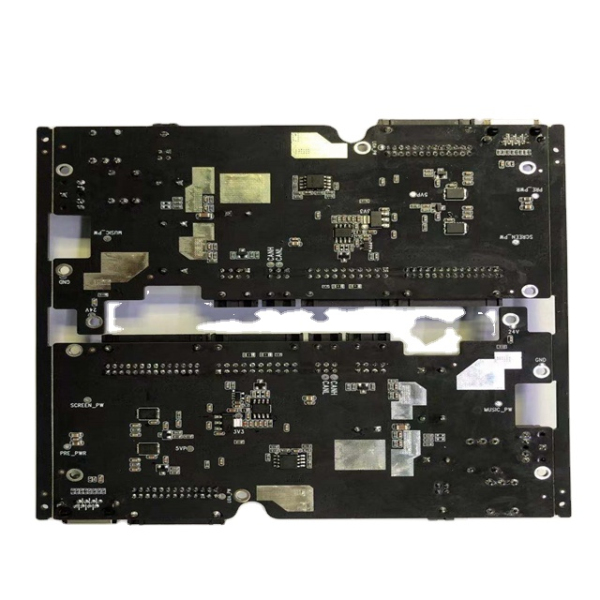

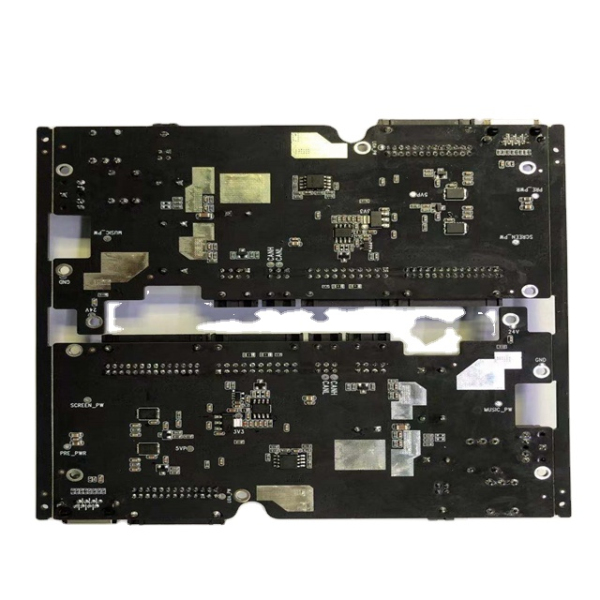

4. Improved durability: As shown in the figure above, these PCBs use multiple insulating layers between circuits, and these layers are bonded with protective materials and different prepreg adhesives. This helps to improve the durability of these PCBs.

4. Improved durability: As shown in the figure above, these PCBs use multiple insulating layers between circuits, and these layers are bonded with protective materials and different prepreg adhesives. This helps to improve the durability of these PCBs.

5. Excellent electrical performance: These printed circuit boards have excellent electrical performance to ensure high speed and high capacity in a compact design.

Introduction to 6-layer PCB

As the name implies, a six-layer PCB includes six layers of conductive materials. It is basically a 4-layer PCB with two additional signal layers placed between two planes. A typical Microwave radio frequency board 6-layer PCB stack has the following six layers: two inner layers, two outer layers and two inner planes-one for power and the other for ground. This design improves EMI and provides better routing for low-speed and high-speed signals. Two surface layers help route low-speed signals, while two internal buried layers help route high-speed signals.

Key factors to consider when designing 6-layer PCB stackups for different applications

The correct stacking of 6-layer PCB manufacturers can help you achieve better performance because it will help suppress EMI, use various types of RF equipment and include several fine-pitch components. Any errors in the stack-up design will seriously affect the PCB performance. Where to start? This is how you correctly choose the stacking method.

1. As the first step of stacking design, it is important to analyze and solve the number of grounding, power and signal planes that the PCB may need.

2. Ground planes are an important part of any stackup because they provide better shielding for your PCB. Moreover, they minimize the need for external shielding tanks.

Here are some proven 6-layer PCB stackup designs for various applications:

1. For dense boards that occupies a small area. Such as HDI PCB: If you plan to route a dense board with a small footprint, you can install four signal planes, a ground plane and a power plane.

2. For denser circuit boards that will use a mixture of wireless/analog signals: On this type of circuit board, you can choose a stack that looks like this: signal layer/ground/power layer/ground/signal layer/ Ground plane. In this type of stacking, the inner and outer signal layers are separated by two package ground layers. This laminated design helps to suppress EMI from mixing with the internal signal layer. The stack design is also ideal for RF equipment because the AC power supply and ground plane provide excellent decoupling.

3. For printed circuit boards with sensitive traces: If you want to build a printed circuit board with many sensitive traces, it is best to choose a stack that looks like this: signal layer/power layer/2 signal layer/ground /Signal layer. This stack will provide excellent protection for sensitive traces. This stack is suitable for High frequency boards that use high-frequency analog signals or high-speed digital signals. These signals will be isolated from the low-speed signals on the outer layer. This shielding is done by the inner layer, which also allows the routing of signals with different frequencies or different switching speeds.

4. For boards that will be deployed near strong radiation sources: For this type of board, the stack of ground/signal layer/power/ground/signal layer/ground will be perfect. This high frequency mixing pressure plate stack can effectively suppress EMI. This stack is also suitable for circuit boards used in noisy environments.

Benefits of using 6-layer PCB:

Because of the six-layer PCB design, they have become a regular function in several advanced electronic circuits. The following advantages provided by these circuit boards make them very popular among electronics manufacturers.

1. Small footprint: Due to their multi-layer design, these printed circuit boards are smaller than other circuit boards. This is particularly beneficial for micro devices.

2. Quality-driven design: As mentioned earlier, 6-layer PCB stack-up design requires a lot of planning. This helps to reduce errors in details, thereby ensuring high-quality construction. In addition, nowadays, all major PCB manufacturers are adopting various testing and inspection techniques to ensure the suitability of these circuit boards.

3. Lightweight structure: A compact PCB is realized by using lightweight components, which helps reduce the overall weight of the PCB. Unlike single-layer or double-layer PCBs, six-layer circuit boards do not require multiple Cable Connectors I/O Connectors to interconnect components.

5. Excellent electrical performance: These printed circuit boards have excellent electrical performance to ensure high speed and high capacity in a compact design.

Product Categories : 0-18Layer FR4 Board > 6 Layer Laser Circuits

Hot Products

Hot Melt Adhesive for WoodworkingChina Supplier Melamine Magic Sponge Foam FactoryNatural Bamboo Fabric Anti Grease Dishcloths Cleaning Kitchen Products FactoryC9 Hydrogenated Resin / Hydrogenated C5 Petroleum Resin for Adhesive Qm120-BC5 Hydrogenated Petroleum Resin (DCPD hydrogenated petroelum resin)Low Odor C9 Petroleum Resin (cold poly) for Adhesives HS130-5C9 Hydrocarbon Resin Petroleum Resin Used for PaintHydrogenated C9 Hydrocarbon Resin for Psa Medicine Grade ResinIndustrial C5/C9 Hydrocarbon Resin Pressure Sensitive Adhesives Hg100-5Strong Base Anion Exchange Resin (201X7 CL)Water Treatment Strong Acid Cation Exchange Resin (001X8 NA)Hot Melt C5 Hydrocarbon Resin Light Color Low OdorEnvironmental C5 Hydrogenated Hydrocarbon Resin Used for Hot Melt AdhesiveC5/C9 Hydrocarbon Resin Used in AdhesiveC9 Hydrocarbon Resin Used in Rubber China FactoryChina Resin C5 Hydrocarbon Resin for Road Marking Paint Factory (001)